How Machina Labs is Transforming Metal Manufacturing with AI and Robotics

In a significant leap forward for the manufacturing industry, a former SpaceX engineer has unveiled a groundbreaking innovation that could redefine how metal parts are produced. Ed, the founder of Machina Labs, has developed a system known as “roboforming,” which leverages advanced robotics and artificial intelligence to shape metal in ways previously thought impossible.

A New Era in Metal Manufacturing

Traditionally, metal manufacturing has relied heavily on sheet metal forming—a process that involves stamping metal into shapes using massive, expensive machinery. This method, while efficient for mass production, lacks flexibility and adaptability. Factories are designed around specific products, making it costly and time-consuming to switch production lines.

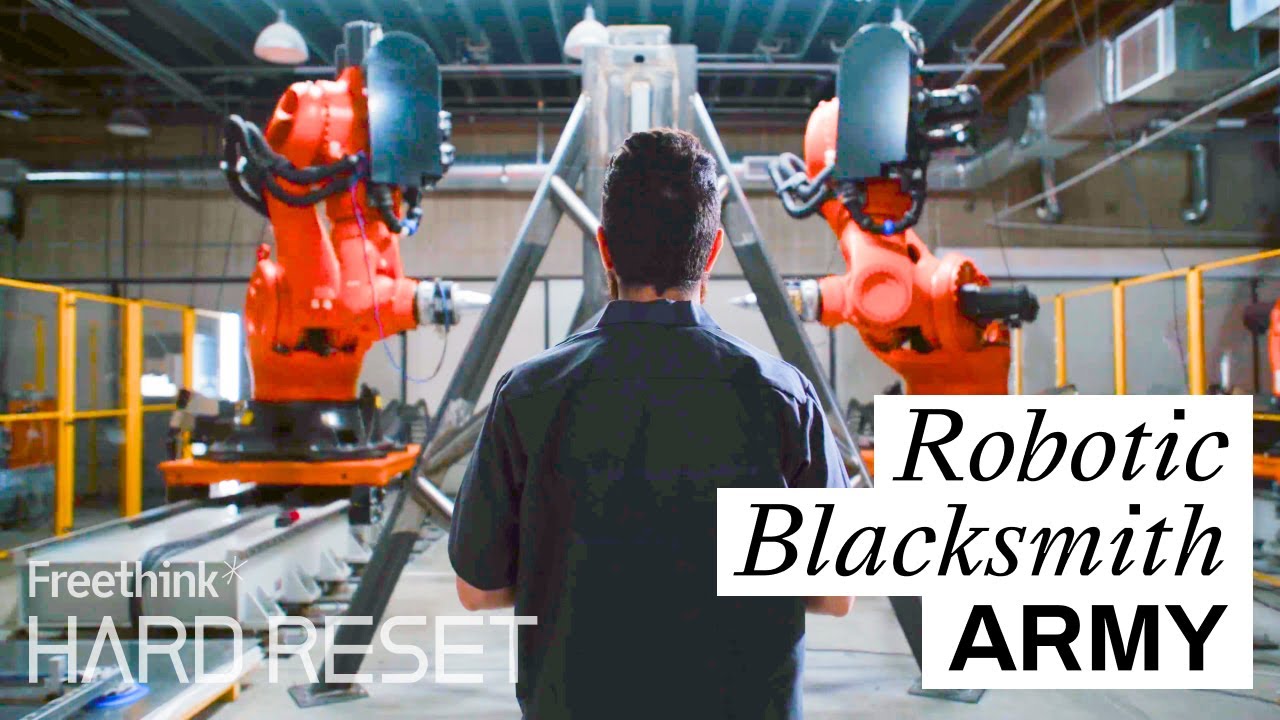

Machina Labs aims to change this with their roboforming technology. Unlike traditional methods, roboforming uses robotic arms to gently and precisely manipulate metal into desired shapes. This process, reminiscent of the craftsmanship of old blacksmiths but enhanced with modern technology, offers unprecedented flexibility and efficiency. “We can design a new car and start manufacturing it today,” says Ed, highlighting the agility of their system.

The Mechanics of Roboforming

Roboforming employs two synchronized robotic arms that work in tandem to shape metal. One arm pushes the metal while the other supports it, preventing it from stretching out of shape. This dance of robotics, controlled by sophisticated AI algorithms, ensures precision and quality. The AI system, equipped with machine learning capabilities, continuously adjusts and improves the manufacturing process, mimicking the intuition and skill of a human craftsman.

The robots used in this process are standard industrial models, some even sourced from platforms like eBay, but they are equipped with custom end effectors and sensors designed by Machina Labs. These modifications enable the robots to exert precise pressure and scan the geometry of the metal in real-time, ensuring accuracy.

Revolutionizing the Industry

The implications of this technology are profound. By making custom manufacturing affordable and efficient, Machina Labs is democratizing the production process. This could lead to a new wave of innovation, allowing smaller companies and individual designers to bring their products to market without the need for massive capital investment.

Moreover, the adaptability of roboforming factories could revitalize local economies. Unlike traditional factories that become obsolete when a product line is discontinued, roboforming factories can be easily reconfigured to produce different items. This flexibility could prevent economic downturns in regions dependent on single industries.

Future Prospects

Currently, Machina Labs is collaborating with marquee customers and working on projects like the Anvil platform, which aims to produce custom car body designs. The potential applications of roboforming extend beyond automotive manufacturing to aerospace, electronics, and even repair services for hard-to-find parts.

Ed envisions a future where manufacturing is as accessible and adaptable as data processing in modern data centers. Designers could upload their specifications to a portal and have parts produced quickly and locally, reducing the need for large-scale, centralized factories.

The advent of roboforming marks a significant milestone in the evolution of manufacturing. By combining the precision of robotics with the adaptability of AI, Machina Labs is not only enhancing the efficiency and flexibility of production but also paving the way for a more decentralized and resilient manufacturing landscape. This innovation could indeed be the “factory of the future,” transforming how we create and interact with the physical world.

For more details, visit Machina Labs and read the full article on Hard Reset.

Warning: Undefined variable $user_ID in /home/iniafrica/public_html/wp-content/themes/zox-news/comments.php on line 49

You must be logged in to post a comment Login